B31.3 Closure Welds

What is a closure weld?

A closure weld, also called a golden weld, as defined in the ASME B31.3 Process Piping Code, is the final weld which connects piping systems or components that have already been successfully leak tested. Closure welds allow for the completion of piping systems where the last weld that closes up the system cannot be included in the pressure test.

In lieu of being proof tested, the closure weld is instead subjected to common in process examinations as outlined in ASME B31.3 paragraph 345.2.3(c). The increase of the in-process examinations decreases the risk of the closure weld being unsound by VT, MT or PT examinations during welding and performing RT or UT on the final weld.

Closure weld in-process examinations include some of the following activities, joint preparation, cleanliness, preheating, fit-up, internal alignment, WPS variables, filler metal confirmation, joint position, VT and MT or PT of root pass, VT between passes, VT of final weld, with RT or UT of the final weld; refer to ASME B31.3 paragraph 345.2.3(c) for specific requirements.

What is the purpose of a closure weld?

A closure weld allows for completion of a piping system in those cases where the last weld can only be made after a pressure test has been conducted.

Closure welds are common where new spools or sections of pipe are installed into existing systems, where isolation for pressure testing is impracticable. The welds in the spool will be pressure tested before installation, and the closure welds are then handled by the rules of ASME B31.3 345.2.3(c).

Requirements

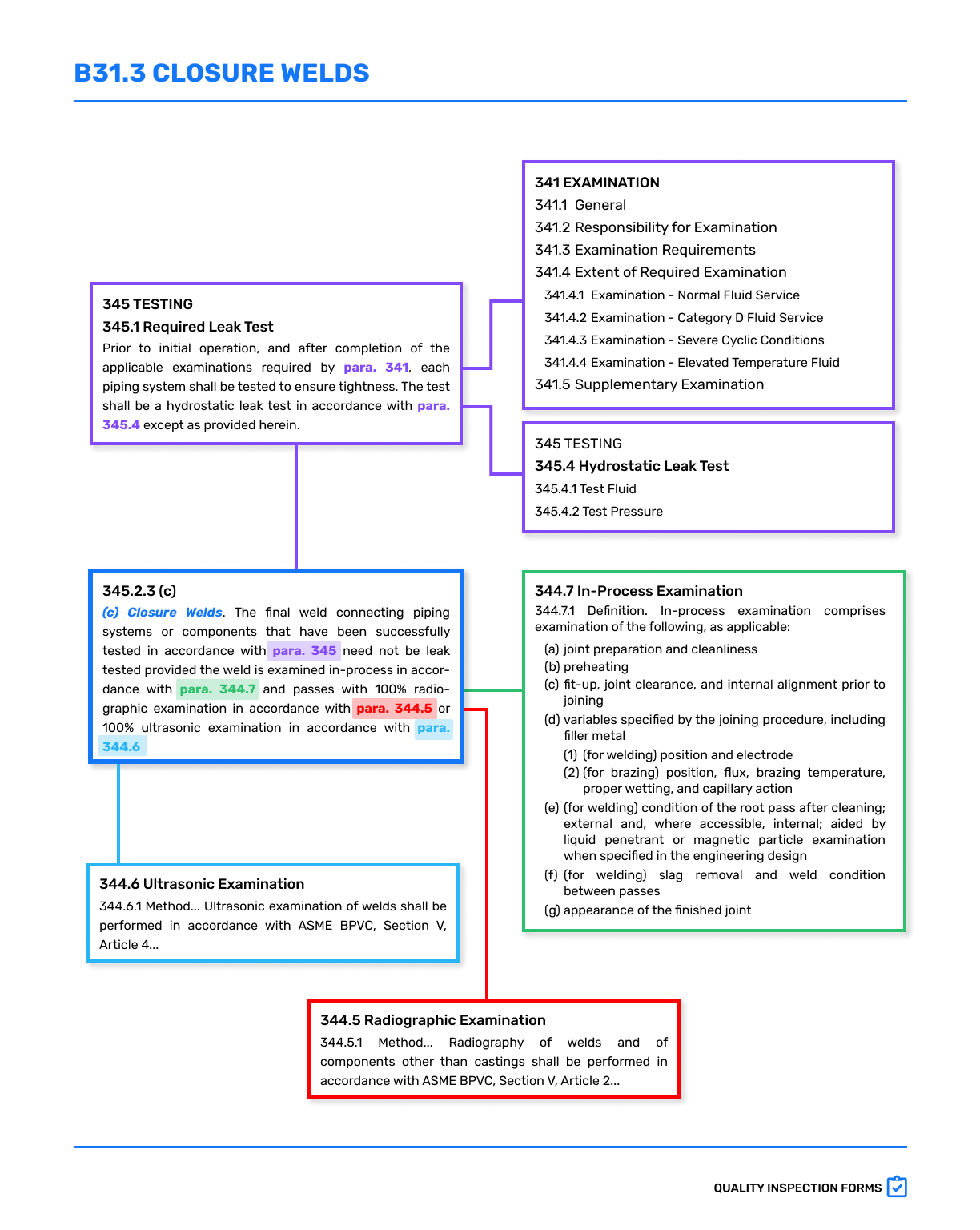

B31.3 closure welds must meet the requirements detailed in the following ASME B31.3 paragraphs

345.2.3(c) Closure Welds

345 Testing / 345.1 Required Leak Test

344.7 / 344.7.1 In-Process Examinations

344.5 Radiographic Examination or

344.6 Ultrasonic Examination

345.2.3(c) Closure Welds

(c) Closure Welds. The final weld connecting piping systems or components that have been successfully tested in accordance with para. 345 need not be leak tested provided the weld is examined in-process in accordance with para. 344.7 and passes with 100% radiographic examination in accordance with para. 344.5 or 100% ultrasonic examination in accordance with para. 344.6.

ASME B31.3 Code Interpretations on Closure Welds

Can there be more than one Closure Weld per piping system? B31.3 Interpretation 20-07 & B31.3 Interpretation 22-16

Are there any fluid service limitations on Closure Welds? B31.3 Interpretation 20-07

Does B31.3 permit 100% RT in lieu of leak testing per paragraph 345? B31.3 Interpretation 22-16

Does B31.3 require the owners approval to apply Closure Weld rules? B31.3 Interpretation 21-10

If socket welds are used for Closure Welds are they required to be 100% RT’d? B31.3 Interpretation 25-34